Maintenance on a button maker

Share

Maintaining your button machine.

Button makers, or at least the good ones require very little maintenance. Remember a good button maker is all metal, NO PLASTIC PARTS!! I have a number of the Tecre style button makers that are 10 years old, they have made trillions of buttons and work with very little maintenance. But these are smaller button sizes, 1" or 1-1/2" round. I also have larger button makers that need more attention and certainly need silicon lube. This is just a smear of lubrication every 500 buttons or so. It's cheap, quick and just becomes a habit. If you have a button maker you definitely need to get some silicon lube. This can also help and certainly does not hurt a smaller button maker.

Relevant question from a customer:

"I've used my button maker to make buttons since purchasing it from you, and I noticed upon pressing my latest set that the machine isn't wrapping the mylar tightly around the edges of the button at the very top of every couple of buttons I make. There is a little bubble of empty space between the edge of my button and the mylar itself. I've double checked that I'm not putting in double sheets of mylar or anything, and I'm using fairly thin paper (28lb) for the designs... What could be causing this? Thanks for your help!

To buy silicon lube online

HOW TO USE SILICON LUBRICATION ON YOUR BUTTON MACHINE.

1. Do not use oil, WD40 or anything but a clean silicon lubricant. Some people use silicon in an aerosol but for the button makers I find stick lubricant works better. This is to protect your images and your buttons. Grease or oil stained buttons will not do well!! Keep your button maker clean!

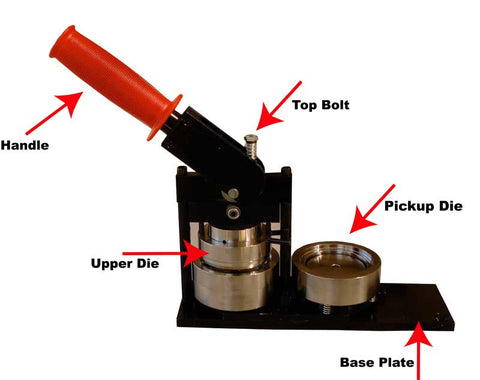

2. Identify the crimp die in your button maker. (See image below) Regardless of style or make of your machine you will have a crimp die where you put the pin-back in. (The pickup die is where you put the shell, image and then mylar) Most crimp dies have a 45 degree surface just visible above where the pin-back goes in. This is the spot! Just put a bit of the stick lube on your finger and rub it around the crimp die. Think of it more as massaging it in as to just smearing it across the surface. The purpose is to fill microscopic damage to the die making it smooth to allow the mylar to pass easily across the surface on the second press.

That usually does the trick and in normal circumstances will be enough. If you have very serious problems or you picked up a used button maker that's been in an attic for 25 years you could:

3. Slide or rotate the lower dies to allow easy access to the upper die. Using a silicon lubricant stick just put a little on your finger as if you were using lip balm, chapstick or lip gloss. Apply a modest smear to the perpendicular walls of the upper die. Massage the lubricant all the way around that upright wall of your upper die. Just enough to leave a thin film of silicon. No need to use much.

4. Go through the button making motion a couple of times to get the lube where you need it. Then make a button as normal. The first button or maybe two will need wiping with a clean cloth. After that your back in business.

5. Repeat every 500 buttons or as necessary. This maintenance requires very little lube. 1 lube stick will last a lifetime.

6. Another problem solver option for older or damaged button makers is to make sure the dies are clean, free from rust or paper, metal or plastic debris. You can use a cloth or if you've got it: compressed air to clear away the grunge. Then soak the dies with the more liquid style aerosol can silicon lubricant and then wipe clean with a clean dry cloth. Search the die for metal burrs and damage. Clean up any damage with very fine emery paper and then clean the die again with liquid silicon to remove any metal dust.

7. Sometimes an older red and black Tecre button maker grinds a bit when it swivels. DO NOT USE WD-40. Using lithium grease, available from any hardware store you can grease the base plate with a smear of silicon grease between the die carrier plate and the base plate. Just smear the base and swivel getting the grease between the two plates.

WHERE TO BUY SILICON LUBRICANT

Lube sticks are available at dollar stores and are inexpensive.

3 comments

Hi Andrew

Thanks for the photos and the movie!! You do not need a spare part at all. Your button maker is jammed. I have written an article to answer your question. Take a look at the article “How to unjam your button maker” in my blog.

Hi Andrew

Please send me some photos. I am not sure what you mean.

Button Guy

send pictures of the part needed. It basically does not wrap the

paper around the backing…as a student pushed down so hard, he

flattened the plate that has a ridge. Sort of hard to explain. Hope

you can help.

Andrew