Buttons, Badges & Pins - People Power Blog

FLEX1000 and FLEX2000 Hobby Button Maker Manual...

If you have a FLEX1000 or FLEX2000 hobby button maker and have lost the instruction manual that was sent with your start-up kit, don't worry! You can now download the...

FLEX1000 and FLEX2000 Hobby Button Maker Manual...

If you have a FLEX1000 or FLEX2000 hobby button maker and have lost the instruction manual that was sent with your start-up kit, don't worry! You can now download the...

Custom Rounded Rectangle Buttons are Here: A Sm...

It’s not often that a new pin shape is introduced, but there is a new button kid on the block. Helloooo Custom Rounded Rectangle Buttons! This button has rounded corners,...

Custom Rounded Rectangle Buttons are Here: A Sm...

It’s not often that a new pin shape is introduced, but there is a new button kid on the block. Helloooo Custom Rounded Rectangle Buttons! This button has rounded corners,...

Say it With a 2” x 3” Rectangle Fridge Magnet: ...

The 2" x 3” Rectangle Fridge Magnet is a great versatile choice. A popular size for family photos and personal statement gifts, this magnet is a favourite souvenir shop idea...

Say it With a 2” x 3” Rectangle Fridge Magnet: ...

The 2" x 3” Rectangle Fridge Magnet is a great versatile choice. A popular size for family photos and personal statement gifts, this magnet is a favourite souvenir shop idea...

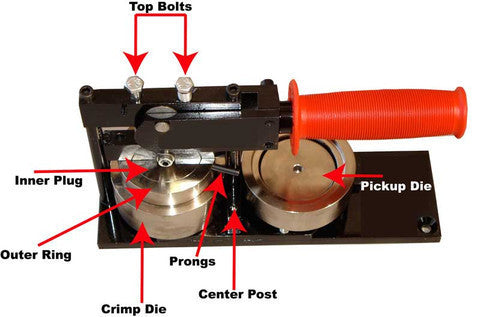

Machine Tune-Ups and Maintenance Services

Every once in a while your trusty hand press might benefit from a bit of TLC. People Power Press can help you keep that machine in tip-top condition with our...

Machine Tune-Ups and Maintenance Services

Every once in a while your trusty hand press might benefit from a bit of TLC. People Power Press can help you keep that machine in tip-top condition with our...

2015 Holiday Gift Guide

Well, it’s that time of year again – holiday shopping season! And this year we've got so many more fun gift ideas for you. You'll be surprised at all the...

2015 Holiday Gift Guide

Well, it’s that time of year again – holiday shopping season! And this year we've got so many more fun gift ideas for you. You'll be surprised at all the...

Unlock the Potential of your 2-1/4" Buttonmaker!

A Whole World Of Products For Your 2-1/4" Button Maker! Ever thought about branching out and making more items that showcase your message, art, or brand? Your 2-1/4” button...

Unlock the Potential of your 2-1/4" Buttonmaker!

A Whole World Of Products For Your 2-1/4" Button Maker! Ever thought about branching out and making more items that showcase your message, art, or brand? Your 2-1/4” button...